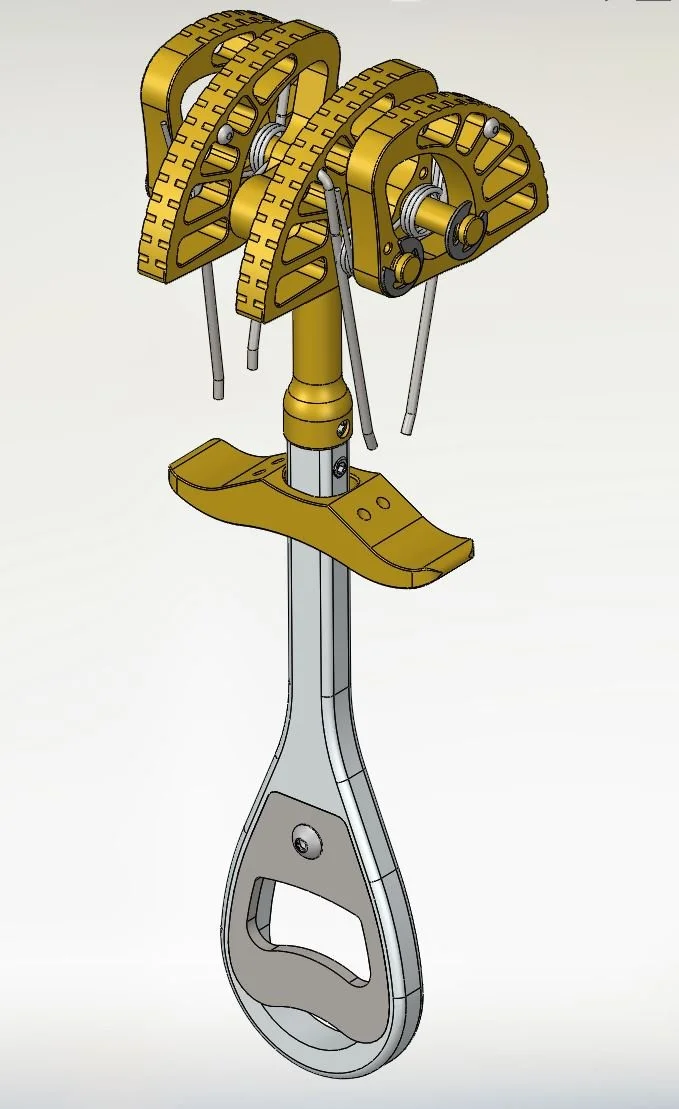

Rock Climbing Cam Build

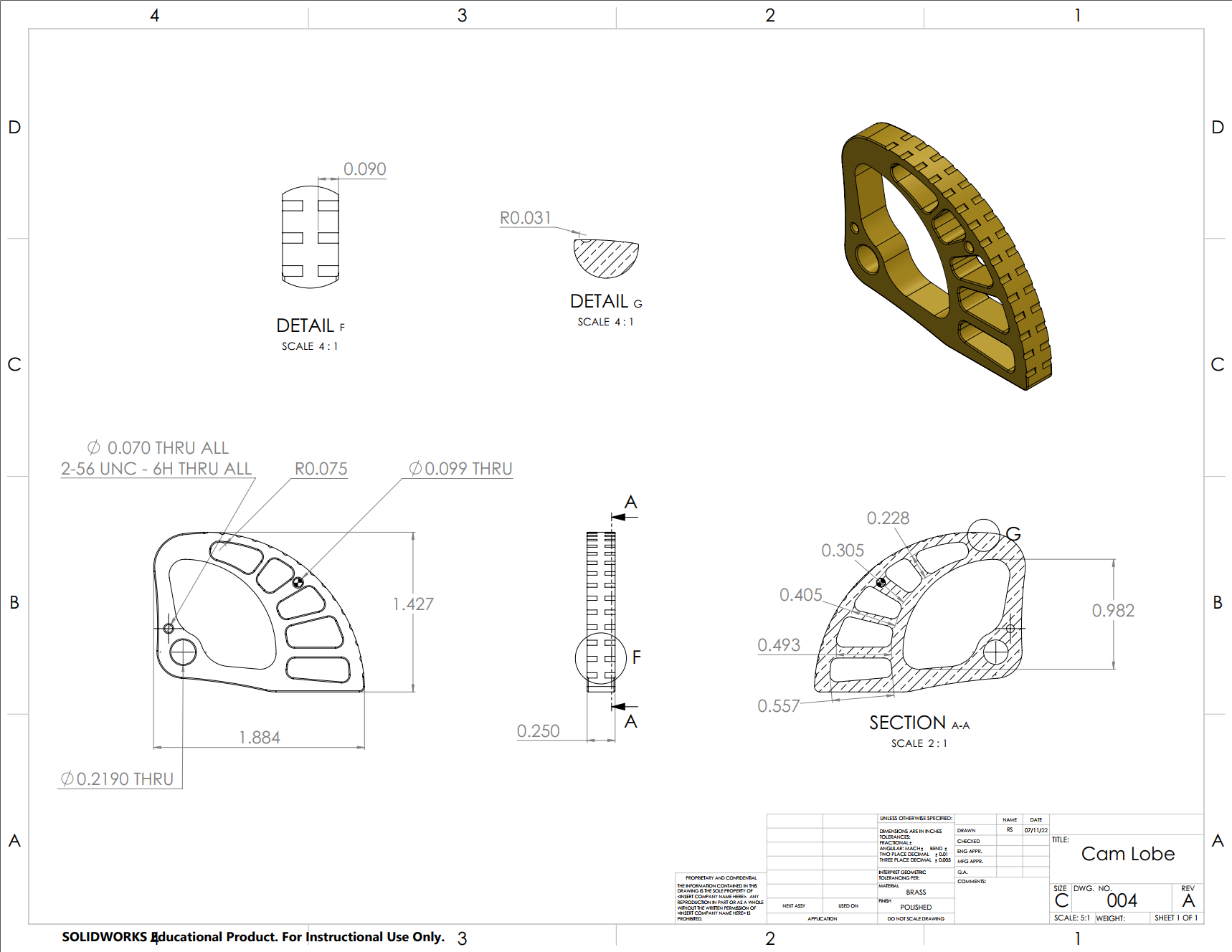

The following project was an exploration into a new realm of machining complexity. The project began with an extensive design process involving reverse engineering a Black Diamond Camalot C4 and custom designing components that were not replicable with available machining techniques. Challenges included designing a complex spring mechanism, press fits, sliding fits and tight tolerances. Materials machined included brass, aluminum and stainless. The finished result actuates as designed and doubles as a bottle opener! All components were designed and machined in house, with a programmable mill and lathe, except for key hardware. *Note, this project did not intend to produce a weight bearing useable camming device.*